By Thomas Grayson, Key Account Manager for Matting & Lighting, Gradus

When it comes to selecting the correct barrier matting for the project, flooring contractors face a range of decisions that directly impact safety, performance, and aesthetics. From construction type to gauge and product combinations, understanding the nuances of barrier matting can make all the difference. Below, we have demystified some of the most frequently asked questions to help contractors make informed choices.

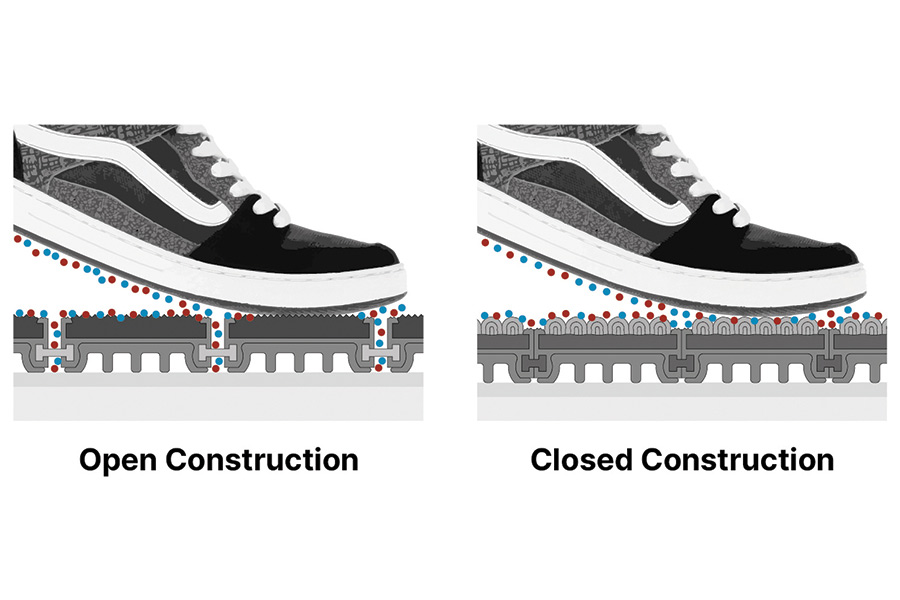

Open vs closed construction: What’s the difference?

One of the most common questions we receive is about matting construction. Open construction mats feature spaces between the wipers, allowing dirt and moisture to fall through into the matwell beneath. This makes them ideal for exterior applications where exposure to rain is a factor. Closed construction mats, on the other hand, have no gaps between the wipers, so debris remains on the surface, perfect for interior settings that are regularly cleaned. In addition to regular cleaning, mats can be lifted to remove debris as well as for deep cleaning of the mat itself. Choosing the right construction type helps maintain safety, appearance, and long-term performance.

How much matting is enough?

Another critical consideration is the length of matting required. The Health and Safety Laboratory (HSL) and the European Floor Safety Association (EFSA) recommend a minimum of 3–4 metres for areas with low peak traffic rates which are defined as up to 78 people per hour. Why does this matter? Because the right amount of matting reduces slips, lowers maintenance costs, and extends the life of adjacent interior flooring. Contractors should assess both foot and wheeled traffic volumes to determine the optimal matting length for each project.

12mm vs 18mm Gauge: Which should you choose?

Barrier Matting gauge is more than a matter of preference, it’s a matter of safety and suitability. A mat with a 12mm gauge can be surface mounted or recessed, making it ideal for retrofit projects or shallow matwells. In contrast, mats with an 18mm gauge are designed for recessing only; surface mounting them may pose a trip hazard. 18mm mats are best suited for new builds or deeper matwells. Selecting the correct thickness and compatible matwell frame is essential for reducing slips and ensuring long-term durability.

Esplanade vs Boulevard: Understanding the product ranges

Gradus offers a comprehensive range of barrier matting systems, including Esplanade and Boulevard products but what is the difference? Esplanade is a collection of aluminium-based primary barrier mats that incorporate wipers to scrape dirt and moisture from various levels of foot and wheeled traffic. Boulevard is a range of textile-based secondary barrier mats that are available in tiles or rolls and designed to absorb residual moisture and debris not captured by the primary matting. For high-traffic environments, combining these products creates a complete entrance system that maximises performance.

Conclusion

Barrier matting may seem straightforward, but the details matter. From product type and gauge to barrier matting combinations and dimensions, each decision plays a role in creating safe, clean, and durable flooring environments. Recognising these nuances can help produce reliable results that are effective over time.

For more information, download the updated Gradus Barrier Matting Systems Catalogue from the website below.

www.gradus.com • thomas.grayson@gradus.com

Please click to view more articles about

> Gradus <