Don’t let sub-floors sink your schedule

Time flies when you’re fitting floors, especially if sub-floors conspire against you to make life more challenging than you anticipated, wrecking the schedule and causing knock-on effects on your installation diary.

But when the going gets tough, the top innovators in the industry get going – there’s a wide range of solutions out there to keep you on spec and on time. And it’s not all about adhesive.

The fastest-drying smoothing compound on the market is Stopgap

Fast-Track 30 by

F Ball which is walk-on hard from just 30 minutes and ready to receive floorcoverings in as little as 45 minutes after application so it is a real ally for installers in a hurry. But there are other solutions to consider that get less attention than they deserve.

“Conversations around fast-track subfloor preparation

products and flooring adhesives often centre around fast-setting, fast-drying formulations,”

says Steve Boulton, Technical Services Manager

at F. Ball and Co. Ltd.

“Sometimes overlooked are products that eliminate the need for certain processes and procedures, thereby dramatically reducing the time it takes to install floorcoverings.These include smoothing compounds that can be applied directly over old adhesive residues, avoiding the need for mechanical removal or priming.

“Thixotropic primers, such as F. Ball’s Stopgap Fill and Prime, which flow freely when stirred but set to a gel-like consistency to fill gaps between raised access panels, can also be applied to flooring grade chipboard prior to the application of a recommended smoothing compound to remove the need for over-boarding with plywood.

“Surface reinforcement systems can also be used to repair weak

or friable screeds rather than having to completely remove

and replace them at significant cost,” adds Steve.

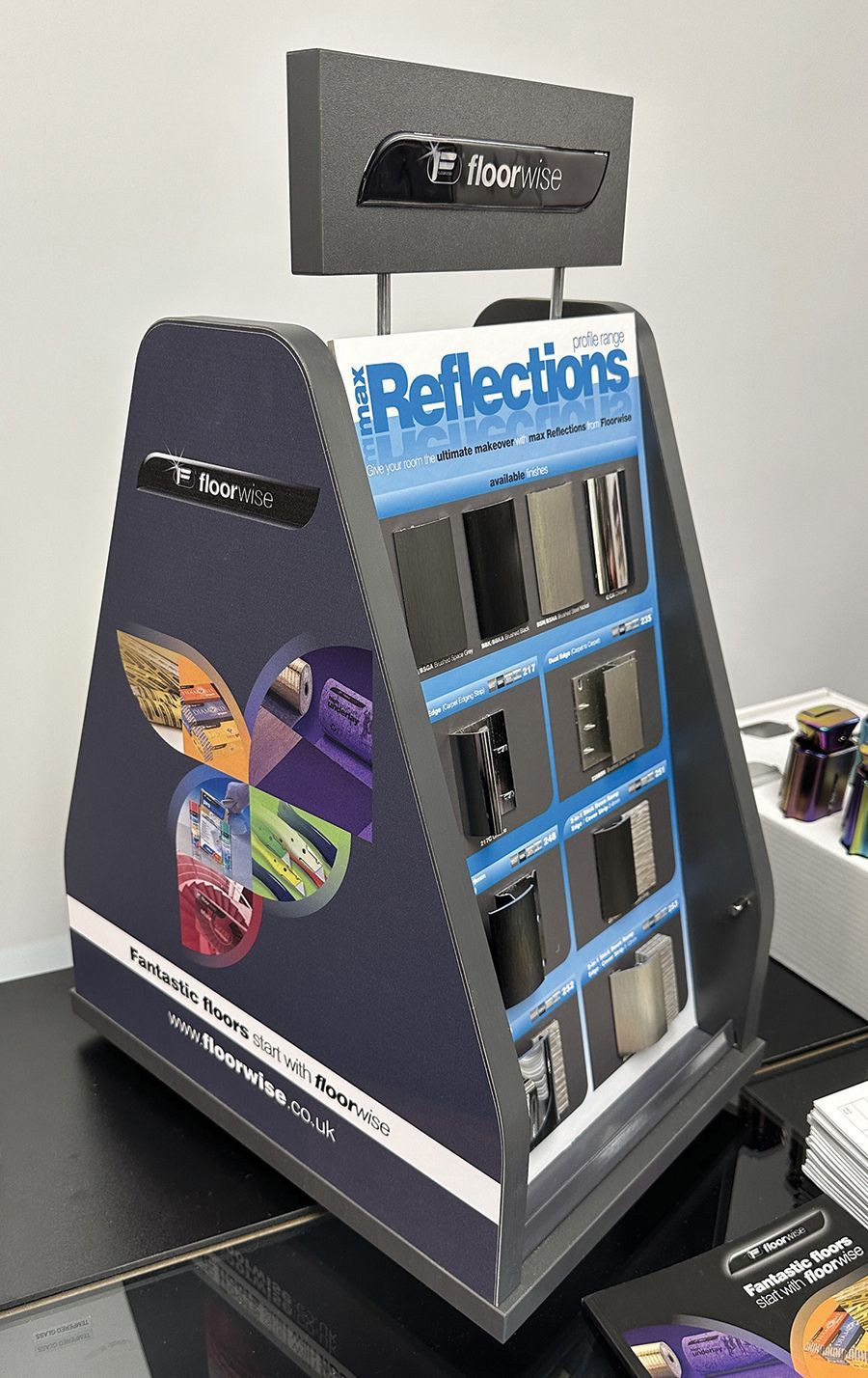

The popularity of Pro-Screed Gold has made it the best-selling floorwise subfloor preparation product ever and with a newly expanded range, the Pro-Screed name is set to become a firm favourite with contractors, retailers and installers looking for a range of versatile smoothing and levelling compounds.

Setting new standards in moisture-tolerant smoothing and

levelling, Pro-Screed Ultra is rapid setting and can be

walked on in just 80-minutes. It is capable of receiving resilient

floors in just three-hours and ceramic tiles can be laid in only

two-hours. Pro-Screed Ultra can be poured over old adhesive

residue and DPMs and no priming is required on most subfloors.

Fibre reinforced for strength and flexibility, the new water-based

Pro-Screed Xtra leveller is suitable for most subfloors. With excellent

flow and a super-fine finish, it’s an exceptionally versatile leveller that’s also moisture tolerant so can be used above or beneath DPMs.

Just like Pro-Screed Ultra, it can be walked on in 80-minutes and has an install time of just three-hours, making it a true all-rounder.

As a plus, floorwise has ensured Pro-Screed Ultra and Pro-Screed Xtra use the latest chemical technology for a non-hazardous formulation that’s more versatile with great open and setting times, and one that’s less harmful for the installer.

Installing flooring in areas affected by residual moisture can be challenging, in terms of application and speed.

Mapei provides the solution, with fast-track combo Mapeproof Primer and Latexplan

Trade Fast.

Mapeproof Primer is a ready-to-use PVDC-based dispersion primer for moisture-resistant non-heated substrates with a RH value of 95% and heated screeds with RH values up to 85%.

Mapeproof Primer is easy to apply with a roller and is colour pigmented to help achieve uniform coverage. The formulation benefits from EMICODE ECI Plus (very low emissions) and Blauer Engel – DE-UZ 113 certification.

Latexplan Trade Fast is a moisture-tolerant levelling and smoothing compound which can be applied 2-5 hours after Mapeproof Primer.

It’s used to smooth concrete floors, cement-based screeds, Mapei Mapecem and Topcem screeds, terrazzo, ceramic tile and natural stone.

It can also be used over most adhesive residues, including bitumen.

Protein-free and low odour, Latexplan Trade Fast sets in just 30 minutes and is light foot traffic ready after 60 minutes. Floors can be installed after just 2.5–3 hours.

Board-level decisions

Gaining increasing traction in the industry is the use of boarded sub-floor solutions which go beyond plywood for a fast professional finish. Sometimes it takes time for fitters to get know these systems, but once they do there is no going back for many.

And for installers used to using flooring grade plywood for their resilient flooring installations, they are increasingly finding variable quality and intermittent availability problems.

Lion Floor is better across the board. What’s more, Lion Floor is

just as easy to install, more cost-effective and comes with

third-party verified EPD that measures its environmental impact as significantly lower.

Lion Floor is pre-conditioned so doesn’t need wetting before installation and it can be cut cleanly and quickly with a knife or saw. Fixed with screws or ring shank nails and suitable for screeds and feather compounds, there’s no longer a reason to choose BS 8203 compliant plywood. Lion Floor is one of a very small number of fabricated underlays which can be used for LVT and other resilient floor coverings that meets British Standards and CFA guidance.

Reliability is one of Lion Floor’s strengths. The dense board is exceptionally resistant to impacts and the construction eliminates the problems that come with the core gaps and overlaps found in plywood. It’s a fast and effective way to deliver a first-class resilient floor installation.

Lion Floor is also a cost-effective alternative to BS 8203 compliant plywood. Made in Finland from readily available wood by-product and free from the highly volatile shipping and material costs encountered by flooring grade plywood, the engineered fibreboard is also consistently affordable.

The Jumpax family by Unifloor is a fast-track floor preparation system designed to provide a super smooth subfloor to receive most glue down and loose lay floorcoverings. It provides excellent sound reduction, is easy to lay and reduces installation time and costs.

The two self-adhesive MDF components of Jumpax instantly smooth over typical irregularities and eliminate the need for screeds, primers, ply boards and nails. It is not necessary to remove old floor coverings, loosening screeds or surface contamination.

Suitable for domestic and contract installations Jumpax offers the ideal solution for problem floors.

Whether it be underfloor heating systems, damaged, cracked, painted and contaminated subfloors, over raised access panels and to protect an existing antique floor Jumpax by Unifloor has the ideal solution.

For more information contact:

F. Ball & Co. Ltd. • 01538 361633 • www.f-ball.com

floorwise • T 01509 673974 • www.floorwise.co.uk

Lion Floor • sales@finfib.fi • www.finfib.fi

Mapei • 0121 508 6970 • www.mapei.co.uk

Unifloor (Jumpax) • 07881 451682 •

www.unifloor-underlay.com

Join the online community on:

facebook.com twitter.com pinterest.com

instagram.com youtube.com houzz.com