The flooring industry has shown impressive tenacity in tackling the environmental agenda and innovating solutions to increase sustainability across the board.

In some other sectors, challenging economic conditions can put the environment on the back burner as a “nice to have”, sometime later! In flooring, the commitment to maintain responsible eco credentials has become core to the activities of many of the main players.

In this feature article we take a wide view – looking at corporate commitments, product innovation as well as recycling and waste management schemes.

BUILDING RESPONSIBILITY INTO

CORPORATE COMMITMENTS

Many major companies take a holistic view of the issue – looking at each aspect of their operation in detail as part of a structured approach to protecting the environment.

Carpet market leader

Cormar is one company paving the way. Committed to reducing environmental impact, Cormar has achieved the ISO 14001 certification, setting high standards in environmental management. They have also invested £750,000 to upgrade their fleet, continuing to reduce CO2 emissions.

As the first manufacturer to partner with Innovate Recycle,

Cormar is pioneering post-consumer carpet recycling in the UK,

with over 175 tonnes of carpets already recycled in 2024.

Their polypropylene ranges are certified as 100% recyclable,

and efforts are underway to implement clear markings for

easy identification of recyclable products.

Looking ahead, Cormar aims to reduce energy use by 30%, switch to renewable energy sources, and achieve net-zero emissions across all manufacturing sites. By involving

customers and retailers in their recycling efforts, Cormar is helping shape a sustainable future within the flooring industry, reinforcing the importance of eco-friendly practices from production to end-of-life.

In the smooths sector, another market leader,

Karndean Designflooring is setting an example with its Karndean Evolve sustainability strategy which commits to reduce absolute greenhouse emissions controlled directly and indirectly by 42% by 2030 and from end of life treatment of its sold products by 51.6% by 2030.

A tangible example of planning for a low carbon future is the opening a new 103,000 sq. ft warehouse at its Evesham headquarters (pictured below, left). The energy efficient building, awarded BREEAM Excellent rating and fitted with 412 solar panels which are expected to generate more than 40% of its electricity requirements, puts the business on course to meet its carbon reduction targets.

Fleur Carson, managing director at Karndean Designflooring, said:

“Our Karndean Evolve strategy sets out ambitious, yet achievable science based targets to reduce our environmental impact at

both local and global scales, and the opening of this new

warehouse is a significant step in our journey. We are proud to

be taking a leading role in the building of a greener future.”

RECYCLING IS SUSTAINABLE, LANDFILL ISN’T

Several well-organised schemes are operating across the flooring industry to minimise the waste destined to be dumped in the diminishing capacity of landfill.

Leading vinyl takeback scheme,

Recofloor, has been celebrating 15 years of successful recycling. Launched in 2009 as a collaborative initiated by manufacturers Altro and Polyflor, Recofloor collects both offcuts and uplifted vinyl for recycling. Material collected is used in new flooring and traffic products such as traffic cones. So far, the scheme has diverted a stunning total volume of nearly 7,500 tonnes of waste from landfill or incineration.

At every stage, the support and involvement of flooring contractors has been crucial to the scheme’s growth. From local fitters to national flooring firms, more and more contractors now see the scheme as their primary vinyl waste disposal option.

For larger quantities of waste, Recofloor will collect from both project sites and contractor premises. Using Recofloor in this way can save up to 70% on waste disposal costs such as skip hire and gate fees.

For the disposal of smaller day-to-day quantities, flooring distributors play an important role. Thanks to a network of Recofloor drop-off points set up by distributor members across the UK, contractors can drop off

day-to-day amounts at no charge.

Recofloor Scheme Manager Carla Eslava commented:

“Our achievements over the last decade and a half are due in no small part to the efforts and enthusiasm of all our members - we couldn’t be prouder of their commitment to responsible waste management practices.”

For rugs, the Take Care Program from

Louis De Poortere

is an integral part of its circular Ecorugs collection, which aims to reach 100% recycled content directly from old rugs.

Alan Russell, sales director, explains more:

“With Ecorugs we’ve set the stage to reach 100% recycled content

for every new rug. The aim is that every new Ecorug is made from

old Ecorugs, bringing a circular production process. By using a

100% PET construction – currently using 20% rPET – we can recycle old rugs and turn every kilogram into new raw material.

“However, in order for us to reach this goal, we need to make sure that our rugs are returned directly to us for recycling by our partners and this is where the Take Care Program comes into play. Through

a QR code on the rug’s label, at the end of the rug’s wanted life, owners simply scan the code and arrange a free collection of the

rug, so that it comes directly back to us,”

he says.

From there, LDP decides whether it can be cleaned and repurposed for an extended life, or whether it needs to be recycled into raw material for a new Ecorug. The Take Care Programme solves two key challenges for product sustainability – extending the life of products and proper recycling – all while making it easy for the consumer.

Underlay leaders

Ball & Young

offer a Take Back scheme on Cloud 9 offcuts to customers for a number of years. They reuse these offcuts in the manufacturing process, which extends the products’ life cycle.

“We are committed to driving full circularity and this is the first step,” said Pete Ward, Head of Operations at Ball & Young.

“Under the scheme, we provide eligible customers with two one-tonne bags to store their offcuts. Once full, our drivers come back around to check and collect them. Of course, our goal is to expand the Take Back scheme to more customers.”

Floor preparation and adhesive products specialists

F. Ball and Co. Ltd. is expanding the scheme that provides contractors with a convenient means of disposing its recyclable packaging.

It will increase the number of locations at distributor partners across the UK where contractors can effortlessly dispose of empty recyclable F. Ball buckets and bottles in branded receptacles, for free.

F. Ball has introduced recyclable packaging for a number of products, with much of the new packaging itself manufactured from recycled materials, allowing it to be reprocessed multiple times.

These include recyclable ‘eco pouches’ for its floor repair and finishing compounds, which require significantly less plastic to produce than the products’ previous packaging, and fully recyclable versions of five and

20 litre bottles plastic bottles used for liquids, including primers and tackifiers.

Subject to the continued success of the programme, there are plans for it to be further rolled out to achieve more widespread geographical coverage.

ECO INNOVATION DRIVES PRODUCT DEVELOPMENT

Every month we see examples of new products where sustainability is central to their specification. This trend is driven partly by growing consumer awareness and sensitivity but also by the increasing demands of the corporate sector where house developers, hospitality companies, architects and commercial specifiers require higher levels of environmental responsibility.

Some recent examples of this kind of product development include BioSisal – made entirely from renewable, natural and organic materials and possibly the most ecological and sustainable carpet available on the market today.

Just launched by the natural flooring company

fibre, BioSisal is crafted from sisal, harvested sustainably in Brazil. The sisal is sourced from small-scale farms that are part of a cooperative, ensuring farmers receive fair prices for their crops. Grown organically without pesticides or fertilizers, BioSisal supports both the environment and the livelihoods of its farmers.

BioSisal’s backing is made from a 100% plant-based felt made from kenaf, hemp and recycled sisal coffee sacks. The backing is then secured to the sisal pile using a purely mechanical and environmentally friendly process which needle punches the backing into the back of the pile. The backing is so stable it allows the floor covering to be fitted traditionally without having to be glued to underlay. At the end of its natural lifecycle, the carpet can be shredded and used as mulch, or composted along with garden waste and other plant based organic materials.

BioSisal is available in a classic boucle design, in five soothing neutral colours and in a 4m width broadloom or as bespoke rugs and stair runners. Hard wearing and durable, the natural fibres help regulate the climate in a room, by absorbing and releasing moisture in the air and works well in conjunction with underfloor heating.

The smooths sector has been especially inventive. Unlike traditional PVC flooring made from fossil fuels,

Beauflor’s Twilight uses an alternative PVC that harnesses used cooking oil and tall oil, a by-product of the wood pulp industry. By eliminating virgin fossil fuel derived materials, the global warming potential of Twilight is 40% lower than Beauflor’s conventional vinyl flooring for residential use.

The introduction of Twilight is a step towards Beauflor’s goal to reduce the impact of its products and to reach zero environmental footprint. It’s part of a framework of actions set-out in the manufacturer’s Route to 2030 as it strides towards its goal by sourcing raw materials, sustainable production practices, ensuring sustainable usage and creating end-of-life solutions.

Picture above : Beauflor Twilight

Twilight is available in 10 striking designs that elevate home interior with contemporary designs that reference unique natural materials and forms. The range uses Beauflor’s digital print technology to achieve a hyper realistic design.

Millions of tonnes of plastic enter oceans and landfills each year, harming ecosystems and increasing global pollution.

Adore Floors has introduced Earth Core, a stylish and durable flooring collection designed with a focus on environmental responsibility.

Earth Core is made from recycled materials, primarily PET from plastic bottles, combined with natural calcium carbonate, creating a resilient product with a reduced environmental impact.

Using advanced digital printing, this collection offers a range of high-quality designs. It features a simple click installation system, ensuring fast and easy installation. With options for integrated padding, it provides added comfort, sound insulation, and long-term durability, making it an excellent choice for both residential and commercial applications.

By transforming plastic waste as flooring, Adore Floors helps combat pollution and offers eco-conscious consumers and retailers a beautiful, long-lasting solution for their spaces.

Every niche of the industry is catered for with environmental initiative

With the increased popularity of trade shows after COVID, exhibition flooring waste is also growing. Waste that often cannot be recycled.

Condor Carpets brings a solution to this versatile industry; Alloa Expo. Carpet made from a single polymer DNA that can be easily recycled.

For Condor Group, a mono-material carpet is not new, but it is for application in the exhibition industry. The fully recyclable exhibition carpet is available in three PET qualities with 6 to 7 colours each and a heavy felt backing. Besides two cutpile products, a loop-pile quality is also available.

They all come in both two, and four-metre widths. The most sustainable version is the EcoClean variant, which features 100% recycled yarn. An additional advantage is that the yarns are manufactured to the highest specifications and contain a specially adapted polymer which ensures that stains do not permanently adhere. Red wine or a cake stain?

You easily brush both out. Ideal for reusing the carpet for multiple exhibition events.

Launched in October 2024, Tessera Topology is the latest range to join

Forbo Flooring Systems’ collection of carpet tiles. Combining contemporary and useable designs with enhanced sustainability performance, Tessera Topology is the first carpet tile in Forbo’s new Evolve+ series.

With the emphasis on combining environmental credentials,

design and performance, Tessera Topology is Forbo’s most sustainable carpet tile range to date. It is manufactured using

Thrive matter by Universal Fibers - a 100% solution dyed nylon

6 which contains 90% recycled content.

Combined with Forbo’s own lean production processes, Tessera Topology contains 75% recycled content, is manufactured using 100% renewable energy (electricity and biogas) and has a very low embodied carbon from cradle to gate (less than 1.5kg CO2 per square metre eqv. A1-A3), which is achieved without offsetting.

From a design point of view, Tessera Topology combines linear angles with soft organic textures to create a contemporary geometric pattern that brings an inherent warmth to a space. With six neutral tones and seven muted accents in a traditional 50x50cm tile format, the range offers flexibility in a range of natural colours.

Altro has published its latest sustainability report, providing a comprehensive overview of the company’s ongoing commitment to sustainable practices. ‘Building better futures’ contains detailed information on Altro’s environmental impact and efforts to reduce carbon emissions; initiatives and programs that promote social responsibility within its communities; innovations in sustainable product development and supply chain management; as well as key performance metrics and benchmarks that track the company’s sustainability goals.

As the inventor of adhesive-free safety flooring more than a decade

ago, Altro has used its expertise to develop and expand its portfolio

to form a collection of smooth and safety floors that need no wet adhesive for installation.

This includes Altro Stronghold 30 adhesive-free, the first adhesive-free flooring designed specifically for the rigours of commercial kitchens. Like all Altro adhesive-free floors, Altro Stronghold 30 adhesive-free delivers huge time and cost savings over traditionally adhered floors as well as up to 50% saving in embodied carbon.

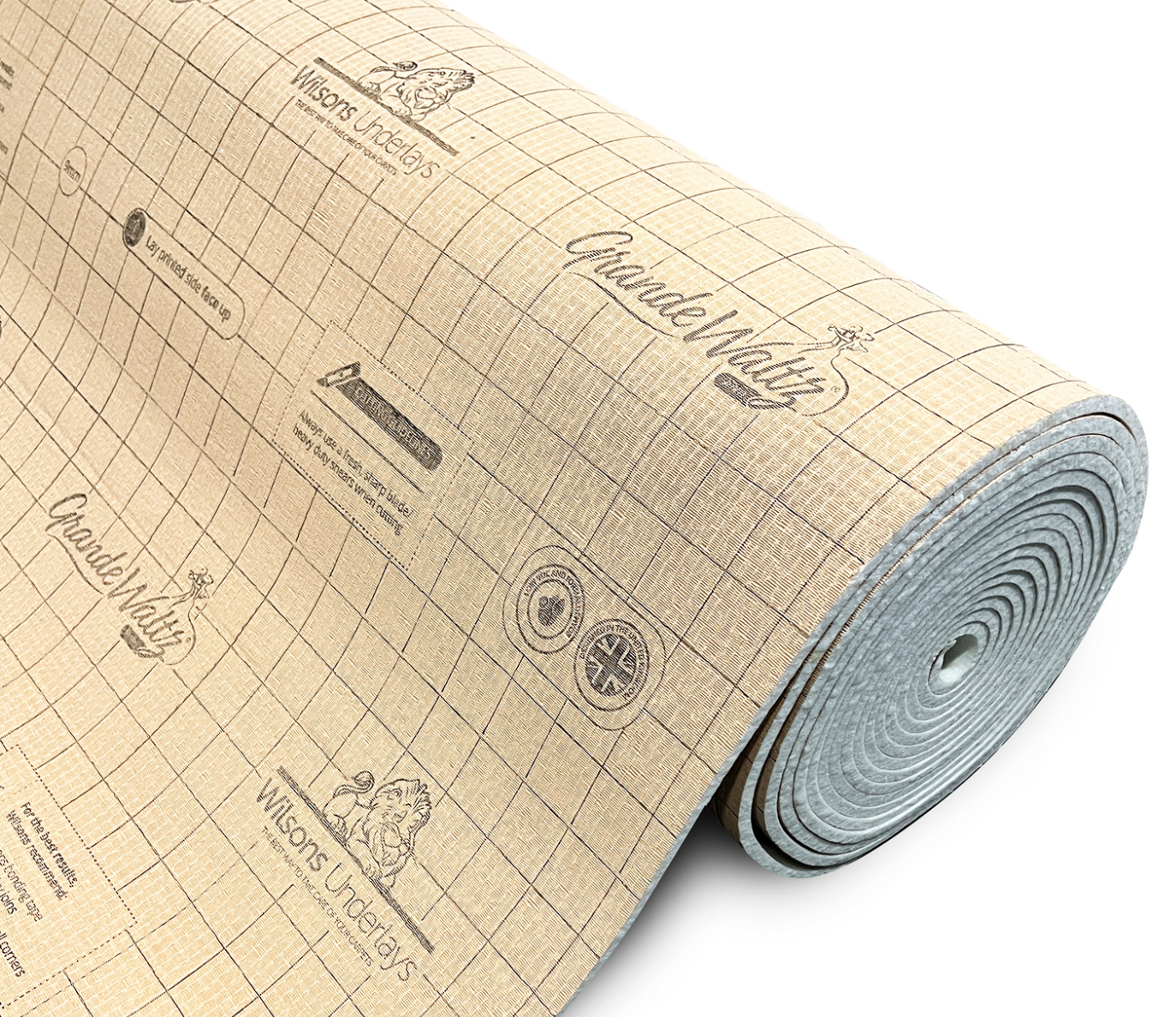

Wilsons Underlays have been delivering high quality underlays and accessories with a friendly smile for almost a decade now, but they never stop innovating and finding new ways to tread lightly on the environment. Their upgraded GrandeWaltz underlay is a prime example, leading the way in product innovation.

It is now made using a recycled-based paper backing which uses up to 80% recycled materials and 100% recycled foam.

Unlike conventional underlays with bright white appearances achieved through a process called ‘delignification bleaching’, which uses oxides or bleaching agents, GrandeWaltz does not involve any bleaching, which cuts down on the carbon footprint even further.

That’s why GrandeWaltz now has such a natural finish that’s more

eco-friendly than ever, with the same luxurious results and backed by

the rigorous testing and British Standards (BS EN 14499) including International Standards (ISO) that show how excellently they perform. With low VOCs and A+ Air Quality rating, GrandeWaltz reaches a

new high.